Choosing the correct screw size and type for any particular DIY project can make a big difference to its success or failure, but working out exactly which screw or bolt you need can be confusing if you are not used to using them. This guide will introduce you to the many different types of screws you might need for DIY jobs, from simple Wood Screws to the more unusual self-tapping and machine screws.

How to Choose the Right Screw for the Job

There are dozens of different screw sizes and types available. Some screws are suitable for multiple jobs and with several different materials. Others are designed for specific building, construction, or home improvement jobs.

Choosing the correct screws for your DIY projects can make a huge difference to how smoothly the project goes, and how good it looks.

Wood Screws

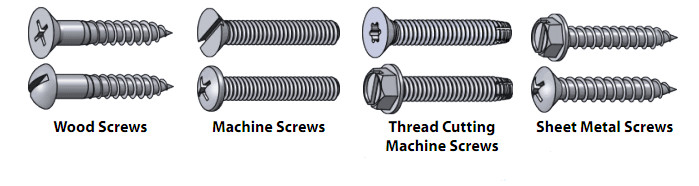

As the name suggests, wood screws are made to be used to attach pieces of wood together. Wood screws tend to be thinner and more flexible than screws for metal or masonry, allowing them to bend slightly as the wood naturally expands or contracts.

Wood screws also commonly have deep threads, which allow them to grip the fibres of timber, and prevent them from being easily ripped out. Screws designed for use with hardwoods often have a double or twin thread which helps them cut into the harder material.

Metal Screws

Metal screws usually have a tighter and smaller thread than wood screws, which allows them to cut into the material more slowly and precisely. Screws designed for use with sheet metal, such as roofing materials or corrugated iron, are almost always self-tapping. That means that blade-like threads on the tip of the screw cut their own hole in the metal, without the need to pre-drill holes.

Self-tapping screws often have hex washer heads for use with a socket driver, but you can also buy them with standard slot and Philips heads.

Masonry Screws

Standard masonry screws are very similar to wood screws, only with a thicker shaft and slightly tighter thread. Screws that are designed to be driven directly into concrete, called frame fixings or anchor bolts, have very thick shafts compared to their small, widely-spaced threads.

Security Screws

Security screws (also called clutch or one-way screws) are designed to be difficult or impossible to unscrew with a standard screwdriver. The heads of the security screws are shaped in such a way that means they can only be turned one way, to tighten them.

This makes them perfect for attaching high-value items, like security cameras, to external walls. They are also often used to affix window security grills, preventing a burglar from easily removing them to gain entry.

Coach Screws

Coach screws, often known as called Lag Screws or Coach Bolts, are heavy-duty fixings used mainly in construction or landscaping. Coach screws are very strong with a relatively wide and thick thread, making them perfect for screwing heavy pieces of timber together. Our guide to building retaining walls with railway sleepers recommends using coach bolts.

Coach Screws almost always have a large hex head, and are designed to be used with a spanner or socket driver.

Machine Screws

Machine screws look like bolts with narrow shafts because they generally don’t have a tapered tip. They can either be used with a nut, or in a pre-tapped hole (a hole with a matching thread cut into it.)

Machine screws are often used to fasten metal components together. Toggle fixings for plasterboard commonly use a machine screw, for example. You can buy self-tapping machine screws, which are usually made from stainless steel.

The Difference Between Twin and Single Threaded Screws

Wood screws, and some other types, are variously described as having single or twin threads. But what does this mean, and what is the difference between the two?

Single Thread Screws

The thread on a single-thread screw features a single continuous spiral around the shaft. Single-threaded screws are usually cheaper than twin threaded and are better suited for use with softwoods.

Twin Thread Screws

Twin thread screws have two separate threads that spiral around the shaft opposite each other. Because each individual thread spiral is spaced widely along the shaft, twin-threaded screws tighten up much faster than single-thread screws. They also tend to be much more secure once screwed into the material.

Types of Screw Head

There is an almost bewildering range of different screw heads available. Some are quite specialised and won’t often be needed for general DIY and home improvement projects. Here are some of the most commonly used screw heads, and where each should be used.

Countersunk Head

Used for general joinery. Ideal if you need the head to be flush with the material.

Raised Countersunk Head

Normally used in ironmongery or if screw caps are going to be used for a cleaner finish.

Dome Head

Used for fixing mirrors and plastic sheets or panels. Head can be topped with a decorative dome or plastic clip-on cover.

Round or Button head

Generally used for fixing sheet material which is too thin to be countersunk.

Bugle Head

Designed to be used specifically with plasterboard and fibreboard. The more extended taper on the head helps to spread the load over a larger area than standard countersunk heads.

Types of Drive

Not only are there several different styles of screw heads, there are also lots of different drive styles. This means the shape of the slot or hole in the head where the tool used to drive the screw into the material is fitted. The most common examples are cross head (Philips) or slot head.

Phillips (Cross head) Drive

The standard drive type for most screws.

Frearson Drive

Similar to Phillips. Requires a Frearson driver for installation.

Slotted Drive

A simple slot in the head.

Combination Drive

A combination of slotted and Phillips drives.

Socket or Hex Drive

A hexagonal hole for use with an Allen Key.

One-way/Security Drive

Installs with a normal slotted driver but can not be removed without special tools.

Square Drive

A simple square hole that requires a special driver. Also known as Robertson Drive.

Star Drive

Also known as Torx. A six-pointed star pattern, specifically designed to prevent cam-out and stripped heads.

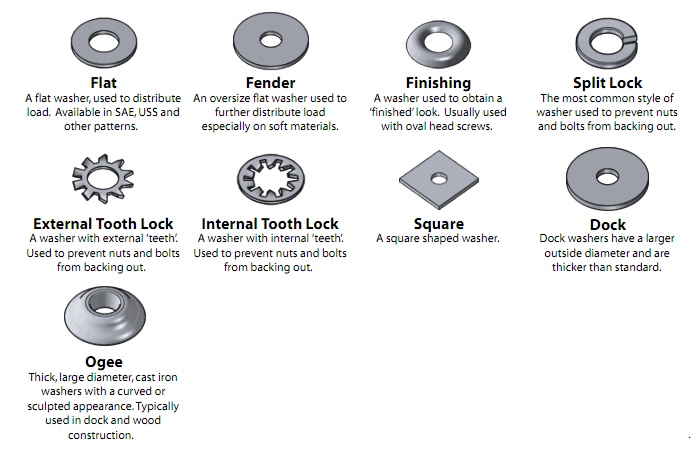

Types of Washer